Single Lock Standing Seam (SLSS) for façade

- Facade

- Clips

- Hidden

- Standing

- Standing seam

- Concealed fastenings

- Horizontal, vertical and diagonal installation possible

- Roof to wall continuity

- Conforming versatility

General information

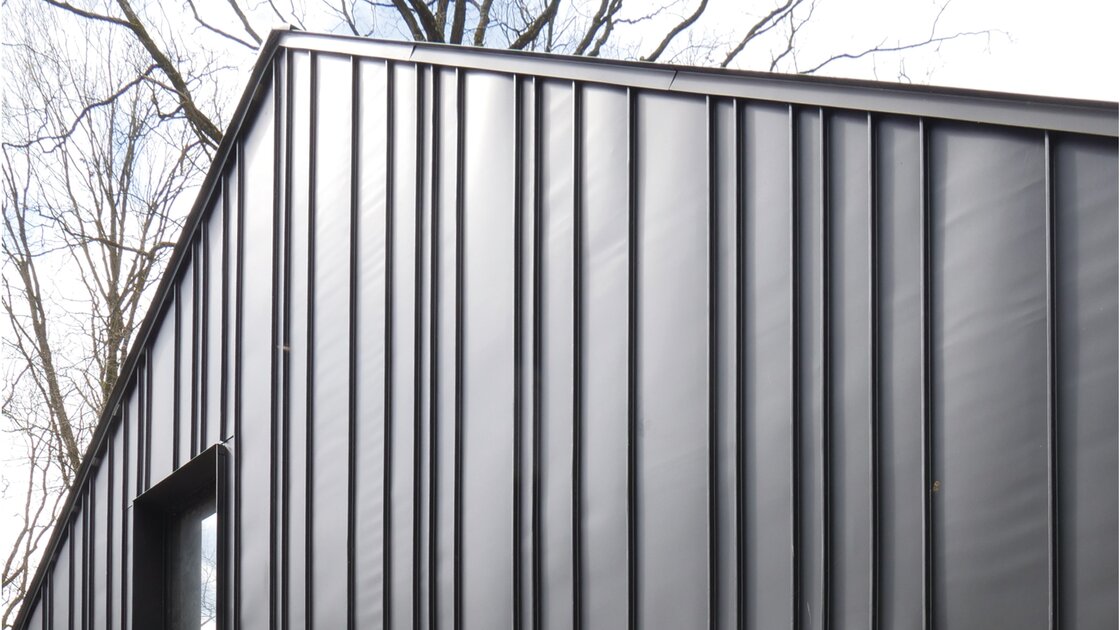

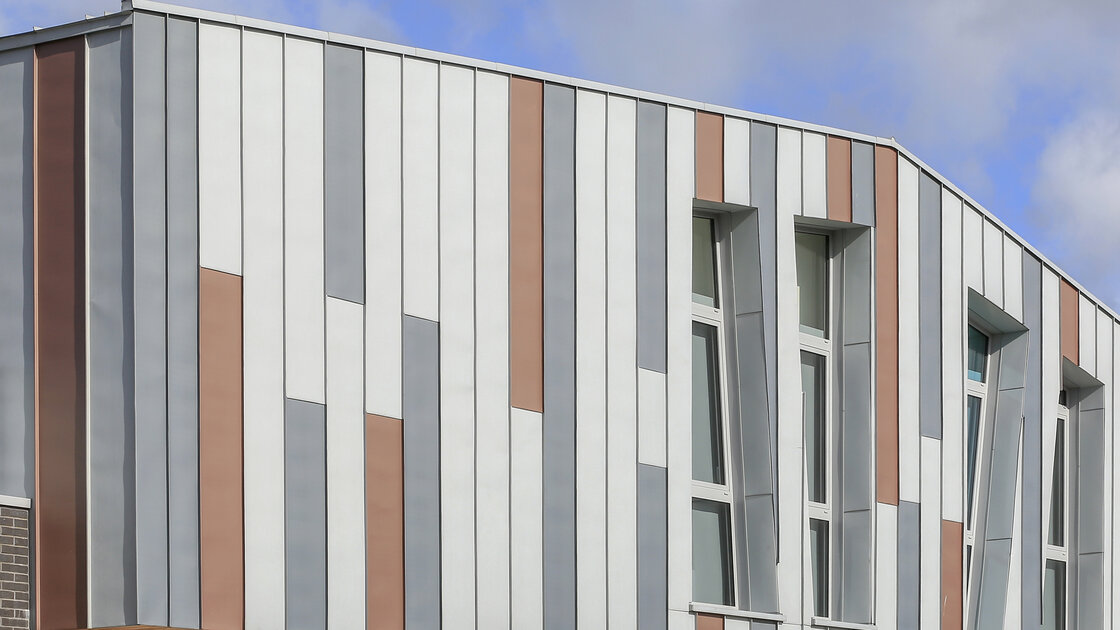

VMZINC Standing Seam is a ventilated cladding system that can be used for both renovation and new build. As the name standing seam implies, the system consists of seams that can be crimped in a single or double lock (for greater flatness single lock seams sometimes referred to as angle seams are recommended).

The system has a traditional look with the seams being 1" high. The panels can be installed horizontally, vertically and at an angle.

This facade system offers the possibility to clad all types of walls: flat, curved or complex forms. Another great advantage of this zinc facade system is that it can be used on both walls and roofs, thus allowing roof and wall to blend as one (standing seam roofs require double lock seams).

Areas of application

Can be installed horizontally and vertically.

Suitable for both renovation projects and new buildings.

All types of buildings: commercial, public buildings, collective and individual housing

Technical data

| Material Thickness | 0.8mm (0.031") |

| Seam Height | 1" or 1.5" (25mm or 38mm) |

| Standard Coverage Dimensions | 16 7/8" OC (1") or 15 7/8" OC (1.5") 428mm OC (25mm) or 403mm OC (38mm) |

| Maximum Dimensions | Horizontal 20'-0" Length (6.09m) Vertical 12'-0" Length (3.65m) |

| Minimum Dimensions | 4" OC width (100mm) 24" length (610mm) |

| Weight | ~1.38 lbs for 16 7/8" (428mm) OC Panels |

Finishes

See all aspects-

AZENGAR PLUS

AZENGAR PLUS -

ANTHRA-ZINC PLUS

ANTHRA-ZINC PLUS -

PIGMENTO Brown PLUS

PIGMENTO Brown PLUS -

Natural zinc PLUS

Natural zinc PLUS -

PIGMENTO Blue PLUS

PIGMENTO Blue PLUS -

PIGMENTO Green PLUS

PIGMENTO Green PLUS -

PIGMENTO red PLUS

PIGMENTO red PLUS -

QUARTZ-ZINC PLUS

QUARTZ-ZINC PLUS

Installation

See all our installation videosDescription

The panels are installed in a sequential order from either left to right or right to left for vertical panels. Horizontal panels must be installed from bottom up.

For panels less than 8'-0" in length only fixed clips can be used.

For longer panels sliding clips must be used towards the bottom on vertical panels and to the left and right of the center for horizontal panels. When using single lock all clips can be fixed. VMZINC clips are made from 304 stainless steel and each clip must resist a pull-out force of 50 daN. It is recommended that screws be used to secure the clips with three being used per sliding clip. The use of nails offers significantly less resistance.

The panels should be installed with the protective film in place. Protective film is recommended to be removed within 60 days post installation.

-

Support

The support must be :

- Rigid and continuous.

- Meet loading requirements in conformity with a minimum pull out strength of 50 daN for each clip.

- Rest on at least 3 bearing structure elements.

- Have no protruding elements on the support.

- Transversal junctions

Fixing System

The L profile of the preceding Standing seam panel and the clips that have been fastened to the panel and fixed to the structure are covered by the U of the next panel, avoiding stresses and lateral traction.

Clips have a dual function:

- Allowing free expansion of the metal.

- Ensuring the mechanical resistance of the entire roof.

The clips from VMZINC are made of 304 stainless steel. The thickness of the fixing clip is 0.5 mm.

The sliding clips have a moving component, which is 0.4 mm thick, and a 70-mm long slot to allow free movement of the panel from VMZINC under expansion and contraction.

The sliding component of these clips must be carefully positioned within the slot at the time of installation. In general, the sliding component is positioned in the middle of the slot.

The clips resistance to tearing is 50 daN.

It is recommended that screws be used to secure the clips.

Three screws per sliding clip is recommended. The use of nails offers significantly less resistance, but in the event of using nails contractors are advised to use ring shank nails.

.jpg?width=1120)

.jpg?width=1120)