Flat lock panel

- Facade

- Clips

- Hidden

- Reveal

- Flat lock panels

- Concealed fastening

- Covered by Code of Practice 143-5: 1964

- Offers great flexibility on panel size and shape

Overview

VMZINC Flat Lock panels, sometimes known as shingles, are installed on a continuous vented substrate on both renovation projects and new build alike. The system consists of panels with 180 degree hems approximately 25mm wide that interlock and are held on the substrate using cleats. The system allows a great deal of flexibility as flat lock panels can be made to many shapes and sizes. The panels can be square, diamond shaped and rectangular.

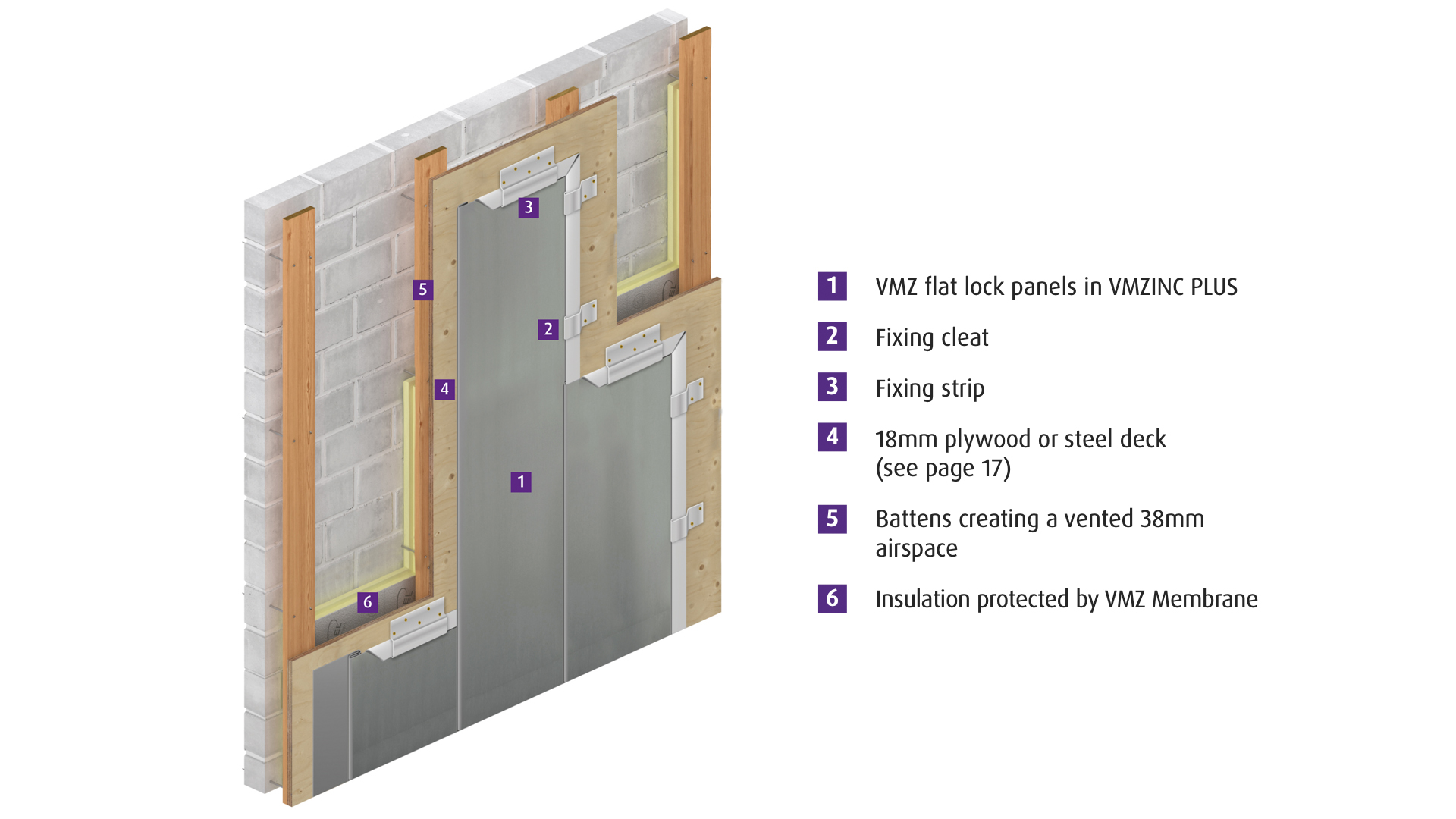

Structure

The system is very lightweight as the panels weigh no more than 8 kg/m2 and can be fixed back to both soft wood open gap boarding and plywood. Both substrates require the use of continuous 18mm thick wood and a vented airspace should be left behind the timber of at least 38mm. VMZINC PLUS must be used on plywood substrates. For vertical surfaces VMZINC can be used on vented plywood with VMZINC Membrane.

For projects where combustible materials such as plywood cannot be used galvanised a 0.7mm galvanised steel deck can be used as a substrate. By combining this with mineral board insulation, all materials in the wall build up are A1 or A2 according to EN 13501. The steel deck must be at least 0.7mm thick and have dimensions allowing clips to be attached at the required spacings. Corrugated steel deck can only be used on vertical surfaces. For all surfaces such as sills, parapets, etc the substrate must be continuous. The 38mm vented cavity can be fire stopped using continuous vertical cavity barriers and intumescent horizontal cavity barriers.

Drawings

Please find below files containing a selection of drawings. Further drawings are available upon request from your specification manager. Please note these drawings are only relevant for Ireland and UK market.

Areas of application

Suitable for both renovation projects and new buildings - Can be installed horizontally and vertically.

Dimensions

| Maximum panel sizes | 600 x 1000 mm 530 x 2000 mm 430 x 3000 mm |

| Panel width | The maximum recommended visible width for a panel is 600mm with the maximum length being 3000mm. |

| Panel thickness | The thickness of the zinc used will depend on panel dimensions with small panels using 0.7mm zinc whereas the larger panels will require 1mm thick zinc. Increased zinc thickness will offer a flatter panel, however increasing panel dimensions will have the opposite effect and may induce some unevenness. |

| Standard flat lock panel sizes | The sizes and shapes indicated in the brochure are standard and are therefore more cost effective than completely bespoke sizes. The sizes indicated correspond to dimensions as seen on the finished wall. Diamond shingles are as standard supplied with non-aligned joints. All panels are delivered with stainless steel clips. |

| Pattern | Width | Length | Nos clips | pc/m2 |

| Square | 235 | 235 | 2 | 19 |

| 420 | 420 | 4 | 6 | |

| 590 | 590 | 4 | 3 | |

| Rectangle | 235 | 470 | 3 | 10 |

| 235 | 940 | 4 | 5 | |

| 420 | 630 | 5 | 4 | |

| 420 | 840 | 6 | 3 | |

| 590 | 885 | 6 | 2 | |

| Diamond - wide | 274 | 215 | 2 | 33 |

| 290 | 230 | 2 | 29 | |

| 432 | 336 | 2 | 14 | |

| Diamond - narrow | 371 | 193 | 2 | 27 |

| 391 | 206 | 2 | 24 | |

| 585 | 301 | 2 | 11 |

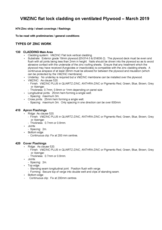

Finishes

See all aspects-

ANTHRA-ZINC

ANTHRA-ZINC -

AZENGAR

AZENGAR -

PIGMENTO Charcoal Blue

-

PIGMENTO Storm Grey

-

PIGMENTO Blue

PIGMENTO Blue -

PIGMENTO Brown

PIGMENTO Brown -

PIGMENTO Grey

-

PIGMENTO Green

PIGMENTO Green -

PIGMENTO Red

PIGMENTO Red -

QUARTZ-ZINC

QUARTZ-ZINC -

Natural zinc

Natural zinc

Documents and drawings

Please enter your E-mail address. We will send you the download link by mail.

Installation

See all our installation videos-

The panels are installed in a sequential order from bottom up. The panels are held in place using cleats which can be stainless steel, zinc or galvanised steel. For larger panels galvanised steel cleats are recommended. The cleats should be fixed at a maximum of 330mm centres. For small diamond shaped panels the hems should be slightly notched thus allowing the cleat to sit securely. When installing large rectangular panels the short side should be fixed with a long fixing strip. It is recommended that screws be used to secure the cleats. The use of nails offers significantly less resistance, but in the event of using nails, contractors are advised to use ring shank nails. The panels should be installed with the protective film in place.